Case Study - Mahindra Sanyo

Mahindra Sanyo is a world leading manufacturer of carbon, alloy and stainless steel for a variety of sectors which aims to integrate sustainability into every facet of its business. Learn here about Mahindra Sanyo's science based targets.

Mahindra Sanyo Special Steel Private Limited, incorporated in 1962 by Mahindra & Mahindra as Mahindra Ugine Steel Company Ltd., is a joint venture between Mahindra & Mahindra India, Sanyo Special Steel Co. Ltd. Japan, and Mitsui & Co. Ltd. Japan. Mahindra Sanyo is a world leading and pioneering manufacturer of carbon, alloy and stainless steel for the automobile, machine building, power and railway sectors. The company has been supplying steel to multinational and domestic clients, including the Indian government, for over 50 years.

Why science-based targets?

Mahindra Sanyo aims to integrate sustainability into every facet of its business. It does this by setting targets and measuring progress against environmental performance, focusing on cutting greenhouse gas (GHG) emissions and reducing fossil fuel-based energy consumption. To demonstrate the environmental credentials of its steel production processes, go beyond statutory requirements, and position itself alongside other world class steel plants, Mahindra Sanyo decided to set a science-based emissions target. The business benefits of adopting a science-based target include cost competitiveness, risk management in the value chain, access to new revenue streams, and safeguarding the company’s future.

At the 2018 World Economic Forum, Anand Mahindra, chairman of the Mahindra Group, pledged to commit the entire Group to the Science Based Targets initiative (SBTi), aligning its emission trajectories with the Paris Agreement. In April 2018, Mahindra Sanyo became the first company in India and the first steel company in the world to have its GHG emissions reduction targets validated by the SBTi.

Meeting the targets

Setting science-based targets has provided Mahindra Sanyo with a firm pathway to reduce its emissions per unit of production.

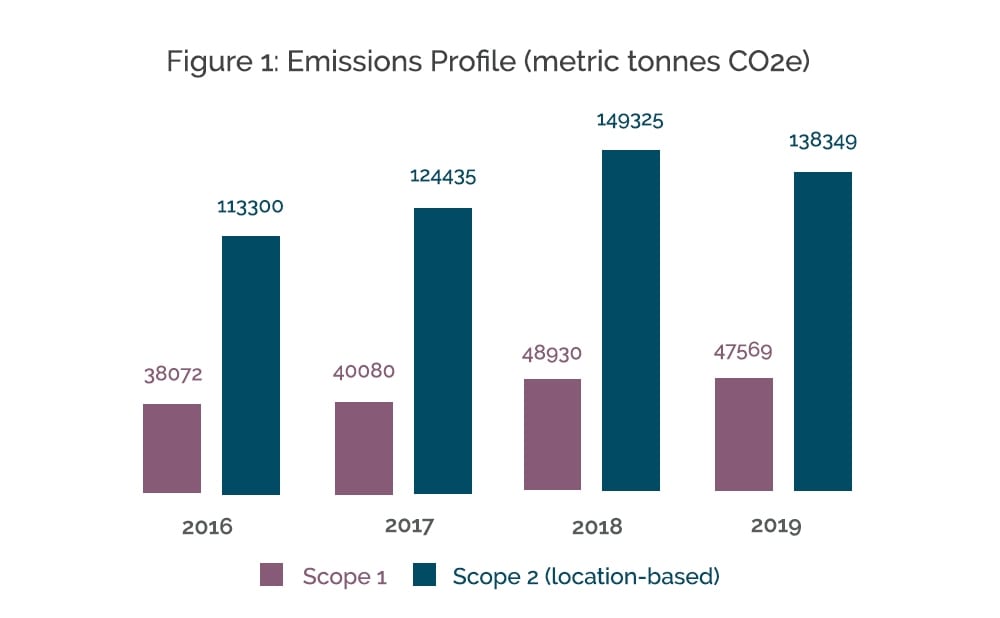

Approximately 20% of Mahindra Sanyo’s total spend is on energy. To reduce its Scope 1 and 2 emissions, the company has invested in energy efficient processes such as: revamping furnaces; reducing cycle times for ladle furnaces; implementing more efficient electric-arc and oxyfuel technologies in furnaces; improving pumps; installing a 6 MW waste heat recovery boiler and new burners for preheating ladles; and switching from oil to natural gas in all furnaces by 2020. The company has made energy efficiency improvements in its buildings by installing low carbon lighting and motion sensors. Between 2018 to 2019, Mahindra Sanyo successfully reduced its Scope 1 and Scope 2 emissions by 6% (Figure 1).

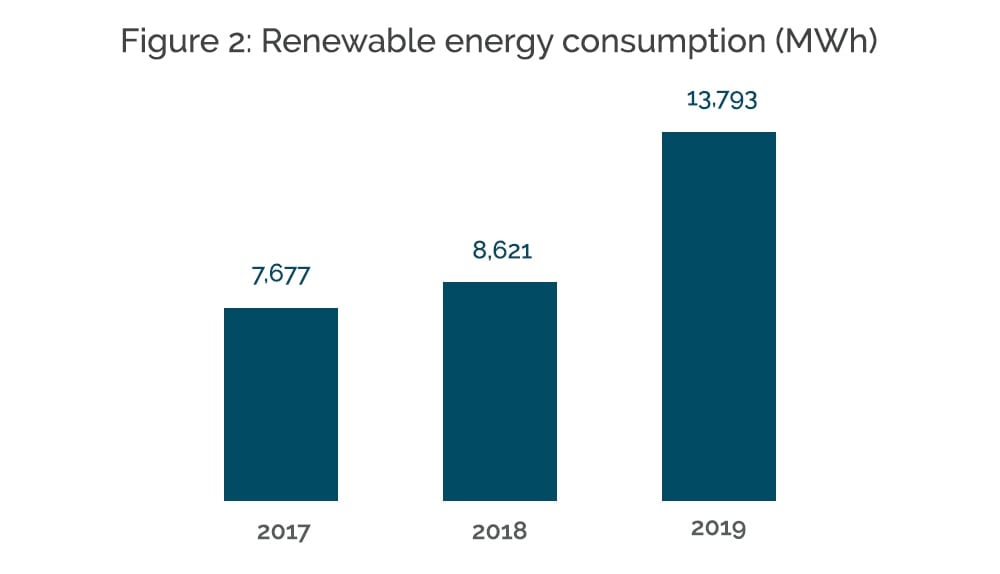

Between 2017 to 18, the company reduced its electricity consumption by 2%, and met 4% of its power requirements through renewable sources. This was helped by the installation of a new 4 MW solar plant and an 80% increase in renewable energy procurement through power purchase agreements from 2017 to 2019 (Figure 2). Mahindra Sanyo has a five-year rolling roadmap to increase its share of renewable energy in electricity consumption. It aims to consume 32% of its total power from renewable energy sources by 2022, either through internal solar plants or renewable energy procurement.

Mahindra Sanyo’s major sources of Scope 3 emissions are purchased goods and services, capital goods, fuel-and-energy-related activities, and upstream and downstream transportation and distribution. The company is examining the key elements of its sustainable operations and will implement new actions in its supply chain to reduce Scope 3 emissions soon.

Mahindra Sanyo explained that science-based emissions reduction targets support its overall business strategy, as energy and GHG emissions are interlinked. The Mahindra Sanyo team said that while the company is responsible for playing its part in preventing dangerous climate change, it also future-proofs its growth and profitability by taking climate action in collaboration with partners in the value chain. For Mahindra Sanyo, science-based targets align its business strategy with the goals of the Paris Agreement, and provide the company with a clear road map for climate action going forward.

This case study was prepared in February 2020 by CDP India.