Case Study - UltraTech Cement Limited

UltraTech Cement Limited is the largest cement company in India, with a capacity of 116.8 million tonnes per annum (MTPA). Find out about UltraTech Cement Limited's science-based targets here.

UltraTech Cement Limited is the largest cement company in India, with a capacity of 116.8 million tonnes per annum (MTPA). Outside of China, UltraTech Cement is the only company to produce over 100 MTPA of cement in a single country. In addition to India, the company also operates in UAE, Bahrain and Sri Lanka .

Why science-based targets?

UltraTech Cement has remained committed to regular and transparent disclosures over the last few years and believes this helped it build and sustain trust among stakeholders. Since 2013, the company has been measuring its carbon footprint and disclosing data through CDP’s environmental disclosure platform (1). CDP India’s Science-Based Targets initiative (SBTi) Incubator helped UltraTech Cement map its science-based targets and the company finds CDP’s reporting platform ideal for measuring progress against climate targets. Reporting though CDP helped UltraTech Cement prepare for the entire target-setting process.

UltraTech Cement’s ambition to grow responsibly and sustainably is helping accelerate the company’s transition to a low-carbon, resilient future. Carbon performance is one of the key pillars in UltraTech Cement’s sustainability strategy, focused on meeting short, medium and long-term climate targets over a 15-year timeframe.

To achieve this vision, the company committed to the Science Based Target Initiative (SBTi) in July 2020, submitting targets for validation in November 2020. In March 2021, UltraTech Cement became the second Indian cement company to have its emissions reductions targets validated by the SBTi.

“A changing climate scenario poses significant challenges for the construction material sector. It equally provides valuable opportunities to develop sustainable products and services. By committing to science-based targets, UltraTech Cement has once again demonstrated leadership in accelerating the sector’s contribution in the global transition to a low carbon economy.” Mr. Kailash Jhanwar, Managing Director, UltraTech Cement.

Meeting the targets

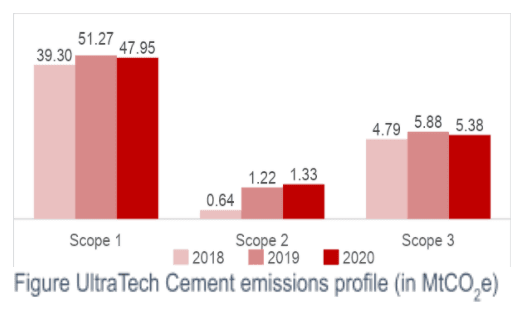

An analysis of CDP’s 2020 data for UltraTech shows a decrease in Scope 1 and 3 emissions from 2019 to 2020. Reductions in Scope 1 emissions are primarily attributed to improvement in clinker to cement blending ratio (2).

UltraTech Cement has taken various steps to reduce its greenhouse gas emissions footprint across operations, focusing on a range of issues such as internal carbon pricing, energy efficiency measures, using alternate fuel resources, increasing renewable energy & waste heat recovery share in the power mix as well as increasing research and innovation. The company has also substituted fossil fuels in kilns with more than 0.3 million metric tonnes of hazardous and non‑hazardous wastes from other industries, installed renewable energy capacity of 99 MW and reached a waste heat recovery capacity of 118 MW in 2020. UltraTech Cement has now successfully met 12% of its electricity consumption through green energy sources and aims to achieve 34% by end of FY 2024.

To improve energy productivity, UltraTech Cement has joined the EP100 initiative and developed a roadmap using emerging technologies, evolving product mix, energy mix and carbon pricing. Initiatives such as EP100 will also help the company reduce its carbon emissions and meet the targets already set under the SBTi. UltraTech Cement has additionally adopted an Internal Carbon Price (ICP) of USD 10/tonne CO2 and follows a structured risk management approach helping it assess and monitor emerging risks. The company has also mapped its climate change risks and opportunities internally, following recommendations made by the Task Force on Climate-related Financial Disclosures (TCFD).

UltraTech Cement believes that its commitment to the SBTi is a key stepping stone in its journey towards a 1.5ºC aligned future. The company has already announced a GCCA Climate Ambition 2050, under which members of the Global Cement & Concrete Association are committing to lowering CO2 footprints across their operations and products, with a vision to deliver carbon-neutral concrete by 2050.

Challenges encountered in the target setting process

With the help of the SBTi India Incubator, UltraTech Cement overcame the challenges faced during their targets setting journey. They were assisted in understanding the range of methods and tools available, along with setting an appropriate base and target year in line with the company’s long-term vision.

Benefits from having a science-based target

Consumer awareness of the importance of sustainable consumption is growing and UltraTech Cement believes that setting science-based emissions reduction targets will help the company enhance its brand reputation among customers, build resilience against imminent regulatory changes and bolster confidence and credibility among investors. Setting these targets will also drive innovation within the company and accelerate progress on the decarbonization agenda at a time when efforts to propel India’s transition to a low-carbon, sustainable economy are underway and growing every day.

The target

UltraTech Cement commits to reduce scope 1 GHG emissions by 27% per ton of cementitious material by FY2032 from a FY2017 base year. UltraTech Cement also commits to reduce scope 2 GHG emissions by 69% per ton of cementitious material within the same time frame. The target boundary includes biogenic emissions and removals from bioenergy feedstocks.

1. UltraTech Cement- CDP Responses

2. Clinker can be blended with a range of alternative materials, including pozzolans, finely ground limestone and waste materials or industrial by-products. The clinker-to-cement ratio (percentage of clinker compared to other non-clinker components) has an impact on the properties of cement. The use of other constituents in cement and the reduction of the clinker-to-cement ratio means lower emissions and lower energy use- Clinker Substitution - Cembureau